Description

DOSATRON – D25WL2IEVVFPPO

Dosing pump for accurate dosing without electricity. Dosatron D25WL2IEVVFPPO has been specially developed for dosing polymers. The model has external dosing where the polymer is led around the pump housing and thus does not enter the pump housing.

DOSATRON D25WL2IEVVFPPO has VF seals and additional V-kit to increase the diameter in the suction unit. The pump housing is made of PVDF material and is partially transparent so you can see if the pump is running even in noisy environments.

Please contact our customer service for further questions.

See our other dosing pumps from DOSATRON here

Maintenance kits:

Rep-kit for dosing part and external part : PJ158 VF

Check valve Ø8 : PJDI074 VF

Rep-kit for engine part : EM004 VF

From wastewater to sludge

As wastewater enters a treatment plant, it is first subjected to rough filtering stages.

It then flows into an aeration tank designed to degrade organic matter and nitrate phosphate ammonia content using microorganisms, forming what is known as sewage sludge.

This particular process requires oxygen.

As wastewater keeps flowing into the treatment plant, more sludge will be produced requiring more and more oxygen thus more energy to produce the oxygen.

To avoid sludge excess (and increased oxygen consumption), some of the sludge is regularly pumped out.

Once extracted, this high-concentration sludge requires a specific process to separate the liquid phase from the solid phase.

How does sludge treatment work?

Sludge treatment is the process of treating and reusing the sludge produced by wastewater treatment plants. Sludge consists mainly of organic and inorganic matter, such as particles of decomposing organic matter, mineral salts, nutrients and micro-organisms. Here’s how sludge treatment generally works:

Extraction of the sludge from the aeration tank or clarifier using specific pumps.

1. Mixing of extracted sludge with a polymer solution injected using a metering pump.

2. Mechanical separation of the liquid and solid phases of the sludge using various machines such as dewatering tables, screw presses, filter press, centrifuges, etc.

3. This separation can also be carried out without machines using drying beds or Geotubes.

4. Sludge valorisation: Dewatered sludge can be valued in a number of ways, including composting, use as agricultural fertilizer, or landfill.

Sludge treatment is important to avoid environmental pollution and to retrieve the nutrients and resources present in sludge. However, it is important to follow current environmental regulations and standards when processing sludge, to ensure environmental safety and quality.

Why inject polymer?

Polymer injection is a technique that can be used in sewage sludge treatment to separate solids from liquids. Polymer is a chemical substance that can be added to sludge to improve its flocculation capacity, its ability to form flakes.

Polymer dosing may require a maturation period, depending on the treatment system.

Here’s how polymer injection can be used to separate liquid from solid in sewage sludge:

Polymer addition: Polymer is added to sludge as a concentrated solution, usually at a rate of a few milligrams per liter.

Flocculation: The polymer binds to particles suspended in the sludge, forming flakes that aggregate and settle to the bottom of the container.

Separation: The flocculated solids are separated from the liquids by decantation or filtration.

Polymer injection is an effective technique for separating solids from liquids in sewage sludge, but it must be used with caution. It is important to follow the manufacturer’s instructions and respect the recommended doses to avoid altering the quality of the sludge and treated water.

Polymers require the use of specific polymer dosing pumps as polymer is a very viscous fluid.

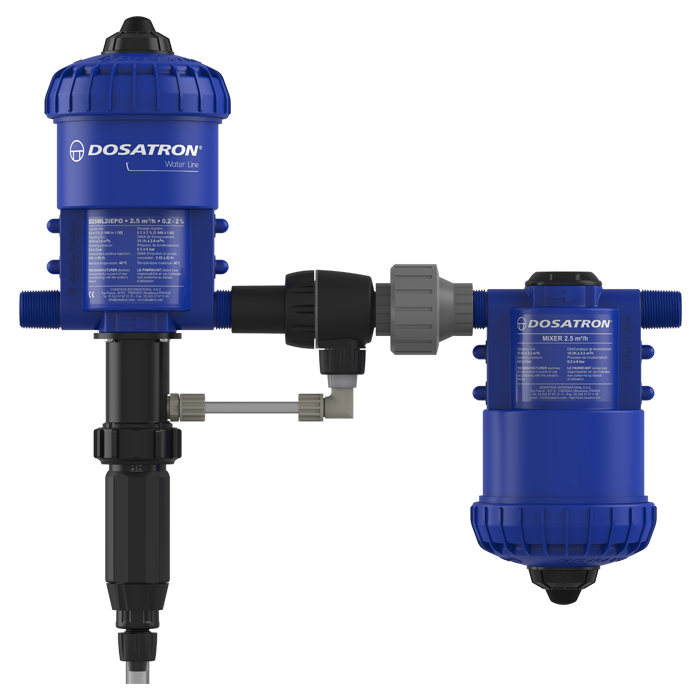

Dosatron polymer dosing pump solutions

The Dosatron D25WL polymer dosing pump range is the ideal solution for liquid polymer injection for small treatment plants (5000 eq hab) or mobile units.

D25WL2 units are easy to install and require no electrical power to operate. They are even compatible with outdoor installations. External injection for easy maintenance.

Installed with its “Mixer”, the D25WL provides maximum homogenization of the water/polymer mixture, optimizing separation of solid and liquid particles.

Dosatron technology and its polymer dosing pump ensure homogeneous mixing of the polymer with the dilution water, and of the diluted polymer with the sludge.

Depending on the process, it can avoid using a specific polymer preparation system, thus saving money and space.

This range can be used to treat sewage sludge, but it is important to note that its use will depend on the nature of the sludge and the chemicals used, as well as the specifications and requirements of the treatment system. It is recommended that you refer to the instructions in the user manual and to current standards to ensure that this product is suitable for your application, and that its use is safe and complies with environmental regulations.